Disclaimer: I guess this is a good time to point out that the Aryeh Cooks segment is more of an Aryeh makes food segment. So baking and any food preparation will apply. With the disclaimer out of the way its time to enter the

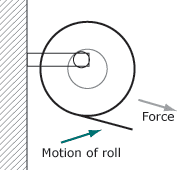

torus.

To begin this post about bagels I will talk about

phyllo which has nothing to do with bagels and is not normally produced as a torus, but I digress. I asked people to suggest what I should make for a future Aryeh Cooks (I do plan on attempting to do every suggestion) and Stacy suggested

spanakopita. Making spanakopita with store bought phyllo dough would be cheating, so I set out to make some. The Greek mother-in-law of a friend of mine once offered to teach me, but I was in a rush to try it on my own and plowed ahead. The phyllo dough I produced did not come up to my expectations, so spanakopita will have to wait until I can arrange a lesson with my friends mother-in-law. In the meantime bagels happened.

Bagels are one of those things that most people would never even think to try and make. Bagels are bought. I tried making bagels once years ago, with very poor results. I set out to do it properly. Two recipes and three attempts later I was successful.

The recipe is as follows:

6-10 Cups of flour (high-gluten bread flour is better for this application, but not a neccesity)

4 Tablespoons yeast

6 Tablespoons of sugar

2 Teaspoons of salt

3 Cups of warm/hot water (the water should be hot but you should still be able to keep you hand in it comfortably)

I do not have pictures of the dough being made. This is because I make dough by hand, which means that my hands are covered with dough and therefor not ideal for the operation of a camera. However, I will give a quick explanation of how it is to be made.

Step 1: Mix the Sugar, water and yeast together and let it sit for 10 minutes to proof the yeast (this is to wake the yeast up and probably not necessary, but it is a ton of fun because the yeast expansion creates a very large head in the bowl it's mixed in. Never forget about the fun in cooking). This step allows the yeast to begin converting sugar and starches into carbon dioxide and alcohol. (What, you though I wasn't going to bring science into this? )

Step 2: Mix half the flour (3 cups) with the salt and then add into the liquids (Use the 6 cup estimate for this. I overestimated the upper bound for the amount of flour because the amount you need will vary based on a number of conditions. Two such conditions are humidity and how packed the flour is). Mix well. Now add about a cup of flour and mix. This is the point where if you are making the dough by hand you should get them messy. Keep adding flour until you can work the dough without bits of it staying stuck to your hands (this is the point where most bread doughs are done). Then work in a bit more flour, you want a somewhat stiff dough. (You will probably end up using around 8-9 cups of flour in the end.)

Step 3: Knead the dough for about 10-15 minutes (If you mixed the dough by hand you can take about 5 minutes off this time, as bringing the dough together by hand also kneads). My personal preference is to keep folding the dough over and over again. I take the dough and fold it in half, then I work it together and fold again. I just keep repeating this process. Kneading dough builds up

gluten chains. Gluten gives bread dough elasticity, which helps the dough in rising and gives bread its chewy quality.

Step 4: Cover the dough with a bit of oil and let it rise. Keep the dough in a dry, warm (about 80 degrees Fahrenheit) place until it approximately doubles in size (about 45 minutes to an hour).

Step 5: Punch the dough down. This is a bit of a misnomer as you don't want to actually punch the dough, you simply want to force the dough down. I just push down on it with both hands to deflate it.

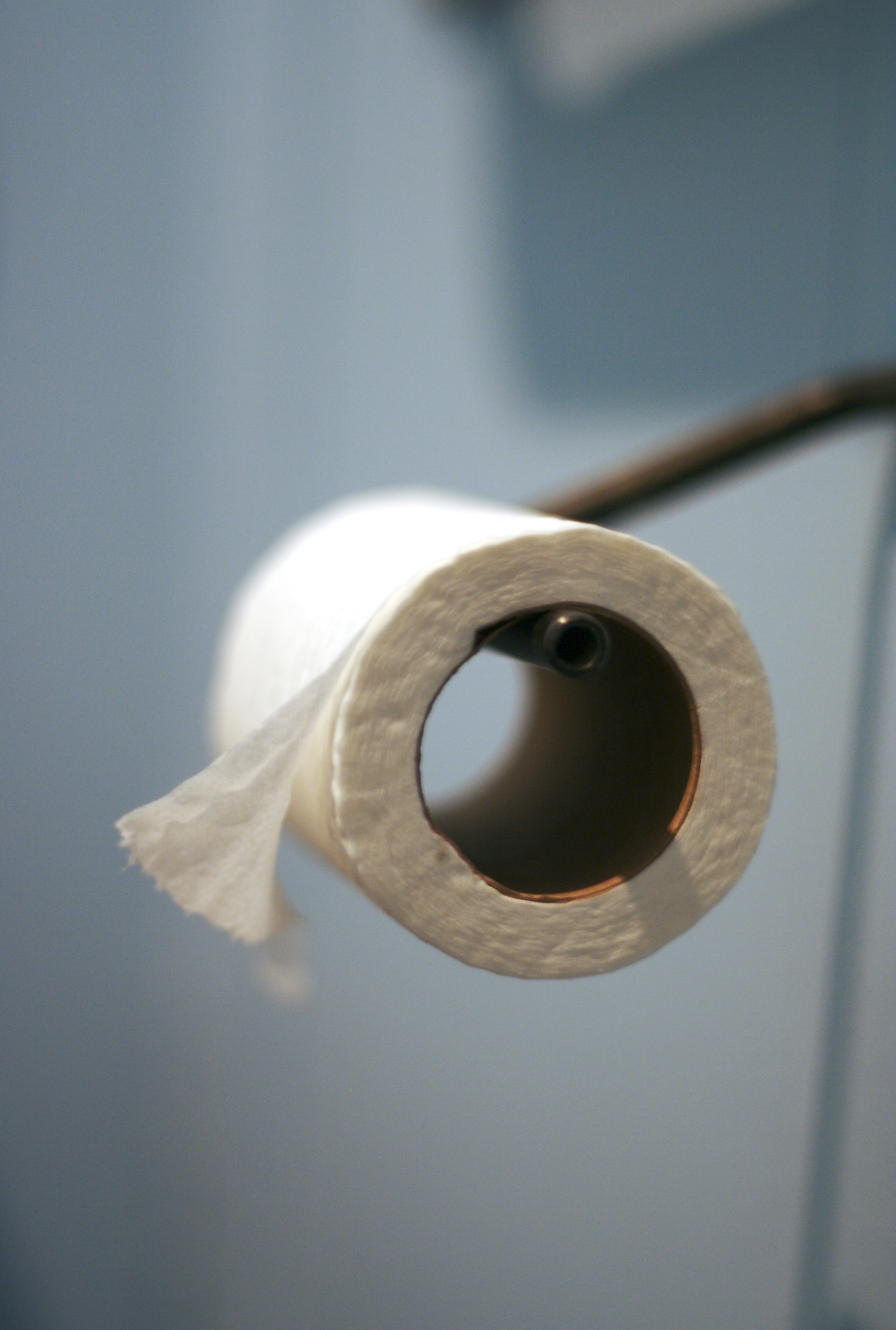

Step 6: Shape the dough. This recipe will give you about a bakers dozen (13) bagels. So start by separating the dough into about 13 pieces. Then on to shaping. There are two schools on shaping. The first has you roll the dough into a snake and then bring the two ends together. The second has you poke the hole through a ball of dough. I subscribe to the second school. Roll the dough into a ball, the smoother the ball the better it will come out. Then simply force a finger through the center of the ball and make into a bagel shape. Here is the important bit, don't shape the dough into a circular cross-section. You want the bagel to be shaped like a length of hollow pipe with a thick wall, this is really important and if you don't do it your bagels will come out flat. Additionally, you want the hole to be much bigger than you think it should be, the dough will rise and shrink the hole. If the hole is to small the bagel will be mushy around the center of the hole. Put the bagels onto a lightly oiled baking sheet, this allows bagels to come off easier when you are going to boil them and helps stop you from mauling them.

I actually did not make the holes big enough. Additionally, this picture was taken after the dough began rising again, so the cylinders have already begun filling out.

Step 7: Half proof the dough, about 10 minutes. This means you should leave the dough alone and let it increase in volume by about one quarter. However, to simplify matters, just let the dough rise for another 10 minutes.

Step 8: Boil the dough. I used a large frying pan, but you can use any pot or pan (I would recommend a wide vessel). Fill the vessel with water and bring to a boil. Add about 6 tablespoons of sugar (this adds a bit of a glaze and a bit of sweetness to the crust. The sugar is not strictly necessary and you can skip it if you want). Bring the water back to a simmer and add as many bagels into it as you can, without crowding. Boil for about 2.5-3 minutes, then flip and boil for the same length of time on the other side. The quicker you can boil all the bagels the better, because the longer they go before boiling the bigger they will grow and you want to avoid this.

Step 9: Move the bagels to a drying rack (I used the rack from my toaster). Then one at a time place them onto a plate containing corn meal. Then put them back onto the baking sheet (corn meal side down). This is also the stage where you can add toppings. Take the topping of your choice and put it on a plate, then simply take the side of the bagel without the cornmeal and put it into the topping. The topping should stick and you are done (you can probably get a little better coverage by adding bits of topping by hand after you dip).

Step 10: After you have all the bagels boiled put them into a 400 degree oven (that you have preheated of course). Bake for 25 minutes, flip (the bagels not you) and back into the oven for another 10 minutes.

At this point allow the bagels to cool for about 10 minutes. Cutting bagels straight out of the oven will result in a mauled bagel and you burning yourself.

The very center of these bagels are mushy. This is because the hole was not big enough. When they where being boiled water was sucked up through the small hole and the center of the bagel was exposed to water for far longer then the rest of the bagel. As a result the center absorbed a ton of extra water. However they came out great with this one exception. Next time bigger holes.

Step 11/Obvious: Eat.

Don't forget to leave suggestions for what I should make on a future Aryeh Cooks.